Bimba Manufacturing produces air cylinders, stainless steel air cylinders, rodless cylinders and a variety of other cylinders. We provide custom-designed air cylinders, quick delivery and a company-wide commitment to quality. Contact us for your cylinder needs today!

A world-class manufacturer of pneumatic, electro-mechanical & control components & systems, Festo has more than 75 years of experience in providing customer-driven automation solutions & service. Our vast selection of air cylinders includes a range of pneumatic cylinders that offer optimized performance for every application, with products meeting demands for the pharmaceutical industry.

Falcon Industries is a machine shop and manufactures hydraulic and air cylinders to your exacting specifications. Our air cylinders are lightweight and durable. We specialize in repairable air cylinders for end dump trailers and belly (bottom) dump trucks, as well as pneumatic cylinders.

More Stainless Steel Cylinder Manufacturers

Stainless Steel Cylinders: Comprehensive Guide to Pneumatic Actuators and Industrial Applications

Stainless steel cylinders are advanced pneumatic devices engineered to use the force of compressed air for linear or rotary motion, playing a crucial role in a wide range of industrial automation and motion control systems. Renowned for their corrosion resistance, durability, and versatility, stainless steel pneumatic cylinders deliver reliable performance in challenging environments, including manufacturing, food processing, medical, chemical, and transportation industries. Whether you require a cylinder to push, pull, open, close, hold, lift, or precisely position components, stainless steel cylinders offer a robust and maintenance-friendly solution adaptable to countless use cases.

Are you researching the best stainless steel cylinders for your automation project or seeking advice on how to select the right pneumatic actuator for your application? This guide covers everything you need to know, from fundamental working principles and technical considerations to specific applications, benefits, and how to choose the ideal supplier. Read on for in-depth answers to common questions about stainless steel air cylinders, their features, and their role in modern industrial systems.

How Stainless Steel Cylinders Work

A stainless steel cylinder operates by utilizing compressed air or, less commonly, hydraulic fluid to drive a piston along a sealed barrel. This linear or rotary motion is harnessed to automate industrial processes, move materials, or actuate mechanical systems. Pressurized air enters the cylinder through specialized intake ports, exerting force on the piston and causing it to move. The cylinder's robust stainless steel construction provides exceptional strength, longevity, and resistance to oxidation, making it ideal for harsh operating environments involving moisture, chemicals, or temperature extremes.

Stainless steel cylinders are available in a vast array of sizes, bore diameters, and configurations to accommodate different force requirements and mounting constraints. Key design variations include:

- Single-acting cylinders: Utilize a single port for compressed air to move the piston in one direction. Retraction is achieved via an internal spring or external mechanical force. Ideal for simple push or pull tasks where a return stroke does not require active force.

- Double-acting cylinders: Feature two ports, allowing air to alternately drive the piston in both directions. This design enables precise bidirectional control and is well-suited for applications requiring rapid, repeatable motion cycles.

- Telescopic cylinders: Employ a multi-stage barrel design and sometimes a pulley mechanism to provide exceptionally long strokes from a compact retracted length. Commonly used in space-constrained environments, such as oil drilling rigs or mobile lifting equipment.

- Rodless cylinders: Eliminate the external piston rod, using internal cables or magnetic coupling to transfer force, thus conserving space and enabling unique motion profiles.

- Rotary actuators: Convert compressed air energy into rotational motion, providing angular displacement for applications such as valve actuation or material orientation.

In all configurations, the core advantage of stainless steel is its ability to resist corrosion and mechanical wear, ensuring long service life with minimal maintenance. This makes stainless steel pneumatic cylinders a preferred choice for demanding industries where downtime or contamination is not acceptable.

Types of Stainless Steel Cylinders and Actuators

When selecting a pneumatic actuator or stainless steel cylinder, it's important to understand the distinct design types available on the market. Here’s a breakdown of the most common options:

- ISO standard cylinders: Built to international standards (such as ISO 6432, ISO 15552), these cylinders offer interchangeability, precise dimensional accuracy, and compatibility with a wide range of pneumatic fittings and mounting accessories.

- Compact cylinders: Designed for use in tight spaces, these feature a short stroke-to-length ratio while maintaining strong force output.

- Round line cylinders: Characterized by a round barrel and end caps, these are frequently used in the food, beverage, and pharmaceutical industries due to their easy-to-clean, hygienic design.

- Tie-rod cylinders: Utilize external rods to hold the end caps in place, providing robust strength for heavy-duty industrial applications.

- Miniature stainless steel cylinders: Suitable for precision tasks, lab automation, and compact assemblies where low weight and small size are critical.

Single-Acting vs. Double-Acting Stainless Steel Cylinders

The choice between single-acting and double-acting cylinders is fundamental in system design. Single-acting models minimize air consumption and system complexity, ideal for clamping, ejecting, or simple positioning. Double-acting cylinders provide maximum flexibility, speed, and force control, making them suitable for automation cells, pick-and-place robots, and repetitive motion tasks.

Searching for a Specific Cylinder Type?

Looking for rodless stainless steel cylinders for space-saving automation, or need a rotary pneumatic actuator for precise angular motion? Use our product selector or RFQ form to compare leading manufacturers and request custom solutions tailored to your requirements.

Key Considerations When Selecting Stainless Steel Cylinders

Choosing the right stainless steel pneumatic cylinder involves more than just sizing for force and stroke. Buyers, engineers, and maintenance professionals should consider the following critical decision factors to ensure optimal performance, safety, and longevity:

- Pressure and Flow Requirements: Assess the required operating pressure (measured in psi or bar) and flow rate to determine the appropriate cylinder bore, rod diameter, and port sizing. Undersized or oversized cylinders can lead to inefficiencies, excessive wear, or incomplete motion cycles.

- Operating Environment: Analyze the application’s exposure to moisture, chemicals, abrasive materials, washdowns, or temperature extremes. Stainless steel pneumatic actuators are ideal for cleanroom environments, food processing, pharmaceutical production, marine, and chemical processing plants due to their superior corrosion resistance and easy-to-clean surfaces.

- Mounting and Installation Constraints: Consider available space, required mounting orientation (flange, foot, trunnion, or clevis), and compatibility with existing automation equipment.

- Stroke Length and Speed: Specify the desired piston travel distance and actuation speed. Fast cycle times may require larger valves or air lines to minimize pressure drop and maximize efficiency.

- Air Consumption and Energy Efficiency: Evaluate total air consumption per cycle to optimize energy use and reduce operating costs, especially in high-volume production settings.

- Maintenance Requirements: Choose cylinders with features such as self-lubricating seals, replaceable wear bands, or easy-to-disassemble designs for simplified maintenance and reduced downtime.

- Regulatory and Safety Compliance: Ensure materials and construction meet relevant standards (FDA, ISO, CE, ATEX, etc.) for your industry—particularly critical in food, beverage, pharmaceutical, and hazardous environments.

Not sure which cylinder fits your needs? Ask questions like:

- What is the maximum load or force required for my application?

- Does my process require washdown-resistant or hygienic-grade cylinders?

- How much space do I have for installation?

- What is the desired actuation speed and frequency?

- Are there any special mounting or safety requirements?

Applications of Stainless Steel Cylinders

Stainless steel pneumatic cylinders are engineered for demanding environments where standard aluminum or mild steel actuators would quickly corrode, seize, or fail. Their robust construction, coupled with advanced sealing and surface finish technologies, makes them an industry standard in the following sectors:

- Food and Beverage Manufacturing: Stainless steel cylinders are the preferred choice for food-grade automation, packaging machinery, bottling lines, and processing equipment. Their smooth, non-porous surfaces resist bacterial growth and withstand frequent caustic washdowns, steam cleaning, and exposure to acidic or salty ingredients.

- Chemical and Pharmaceutical Processing: In environments where aggressive chemicals, solvents, or cleaning agents are used, stainless steel actuators offer unparalleled resistance to pitting, staining, and mechanical degradation.

- Medical and Laboratory Equipment: Precision, cleanliness, and non-reactivity are essential in medical device manufacturing, diagnostics automation, and laboratory robotics. Stainless steel’s biocompatibility and ease of sterilization make it the material of choice.

- Transportation and Automotive: Used in truck air braking systems, vehicle door actuation, and loading dock equipment, stainless steel pneumatic cylinders deliver reliable, maintenance-free operation in variable weather and high-humidity environments.

- Marine and Offshore Applications: Saltwater and extreme humidity demand corrosion-resistant actuators for shipboard automation, hatch opening systems, and offshore oil platforms.

- Aerospace and Aviation: Essential for precision actuation in aircraft systems exposed to temperature extremes, vibration, and corrosive fluids.

- General Manufacturing and Automation: From CNC machine tool changers to pick-and-place robots and conveyor diverters, stainless steel cylinders offer reliable motion wherever contamination control and durability are priorities.

Wondering if Stainless Steel Cylinders Are Right for Your Process?

If you’re considering a switch to stainless steel pneumatic actuators in your facility, ask yourself:

- Is equipment exposed to frequent cleaning, caustic chemicals, or humidity?

- Are contamination risks, product purity, and hygiene critical?

- Does my application require a long service life with minimal downtime?

- Is resistance to extreme temperatures or corrosive agents required?

Advantages and Benefits of Stainless Steel Cylinders

Upgrading your system with stainless steel pneumatic cylinders delivers a host of operational and economic advantages compared to traditional cylinder materials. Here’s why industry leaders choose stainless steel actuators for their automation and motion control needs:

- Corrosion Resistance: Stainless steel’s natural oxide layer protects against rust, chemical attack, and moisture-induced degradation, making it ideal for washdown environments and outdoor use.

- Hygienic Design: Easy-to-clean surfaces and minimal crevices reduce bacterial growth and cross-contamination—critical for food, beverage, and pharmaceutical production lines.

- Lightweight and Compact: Stainless steel cylinders offer high strength-to-weight ratios, resulting in lighter assemblies that are easier to install and transport without sacrificing durability.

- Long Service Life and Low Maintenance: High-grade stainless alloys and advanced seals ensure years of reliable operation, minimizing unplanned downtime and reducing total cost of ownership.

- Thermal and Radiation Stability: Stainless steel maintains mechanical properties across a broad temperature range and resists degradation from UV light or radiation exposure, supporting applications from cryogenics to high-temperature processing.

- Customizable Performance: Available in a variety of sizes, mounting options, and special finishes (polished, electropolished, passivated) to meet unique process requirements. Many manufacturers offer custom porting, stroke lengths, and integrated sensors for advanced automation.

What are the cost benefits of stainless steel pneumatic cylinders? While initial investment may be higher than for aluminum or low-carbon steel designs, stainless steel’s extended lifespan, reduced maintenance, improved safety, and lower contamination risks deliver significant long-term savings and regulatory compliance advantages.

Comparing Stainless Steel Cylinders vs. Other Materials

How do stainless steel pneumatic actuators stack up against aluminum, plastic, or carbon steel cylinders? Stainless steel offers unmatched performance in harsh or regulated environments, whereas aluminum is more suitable for dry, non-corrosive settings where weight is the primary concern. For buyers prioritizing hygiene, chemical resistance, and mechanical strength, stainless steel remains the clear industry standard.

How to Choose the Right Stainless Steel Cylinder Supplier

Selecting a qualified stainless steel cylinder manufacturer or supplier is critical to ensuring product quality, technical support, and delivery reliability. Here are key steps and questions to guide your purchasing process:

- Evaluate supplier capabilities: Does the manufacturer offer a broad range of ISO-certified stainless steel cylinders and pneumatic actuators? Do they support custom engineering, rapid prototyping, or small-batch production?

- Review technical support and documentation: Look for detailed datasheets, CAD models, installation guides, and engineering assistance to streamline integration with your automation system.

- Check compliance and certifications: Ensure the supplier’s products meet relevant industry standards (FDA, ISO, ATEX, RoHS) and offer full traceability for critical or regulated applications.

- Compare lead times, pricing, and after-sales support: Request quotes from multiple suppliers to balance cost, delivery, and support. Look for partners with responsive customer service and local stock for urgent needs.

- Assess reputation and industry experience: Choose manufacturers with proven track records in your industry, positive customer reviews, and a commitment to continuous improvement.

To make sure you have the most beneficial outcome when purchasing Stainless Steel Cylinders from a Stainless Steel Cylinders Supplier, it is important to compare at least 4 or 5 companies using our list of Stainless Steel Cylinder suppliers. Each Stainless Steel Cylinders company has a business profile page that highlights their areas of expertise, technical capabilities, and a contact form to communicate directly with the manufacturer for more information or to request a quote.

Review each Stainless Steel Cylinders company website using our patented website previewer to compare specialties, then use our streamlined RFQ form to contact multiple suppliers with a single request. This approach saves time, ensures competitive pricing, and helps you identify the ideal partner for your automation, manufacturing, or process control project.

Frequently Asked Questions About Stainless Steel Cylinders

- What is the lifespan of a stainless steel pneumatic cylinder? With proper sizing and maintenance, stainless steel cylinders can provide reliable service for 10+ years, even in harsh or corrosive environments.

- Can stainless steel cylinders be used with hydraulic fluids? Yes, though most are optimized for pneumatic (air) use. If using hydraulic fluids, confirm seal compatibility with the supplier.

- Are there hygienic or clean-in-place (CIP) stainless steel actuator designs? Many leading manufacturers offer specialty CIP and SIP (sterilize-in-place) certified cylinder designs for regulated industries.

- What is the typical lead time for custom stainless steel cylinders? Lead times vary by supplier and complexity but typically range from 2–6 weeks for custom builds.

- How can I size a stainless steel cylinder for my application? Determine required force, stroke, mounting style, and environmental conditions, then consult with the manufacturer or use an online sizing tool for recommendations.

Ready to Source Stainless Steel Cylinders?

Whether you’re upgrading existing automation, designing new equipment, or looking for improved reliability and hygiene, stainless steel pneumatic cylinders offer unmatched performance, safety, and value. Browse our directory of top manufacturers, compare technical options, and request quotes to ensure you get the best actuator for your needs. For expert guidance, contact our team or explore our Pneumatic Cylinder Resource Center for additional articles, specifications, and case studies.

Air Cylinders

Air Cylinders Assembly Machinery

Assembly Machinery Ball Bearings

Ball Bearings Electric Motors

Electric Motors Fractional Horsepower Motors

Fractional Horsepower Motors Friction Materials

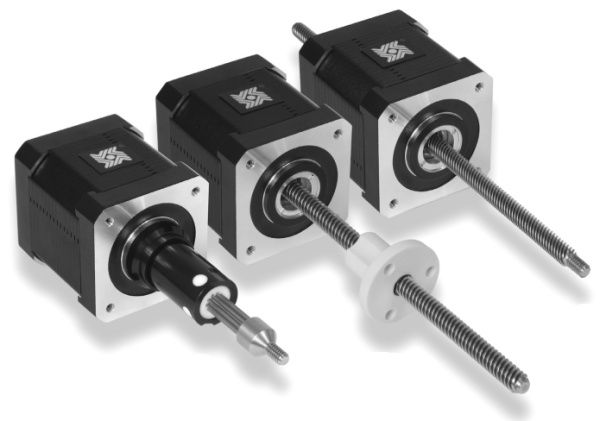

Friction Materials Linear Actuators

Linear Actuators Linear Bearings

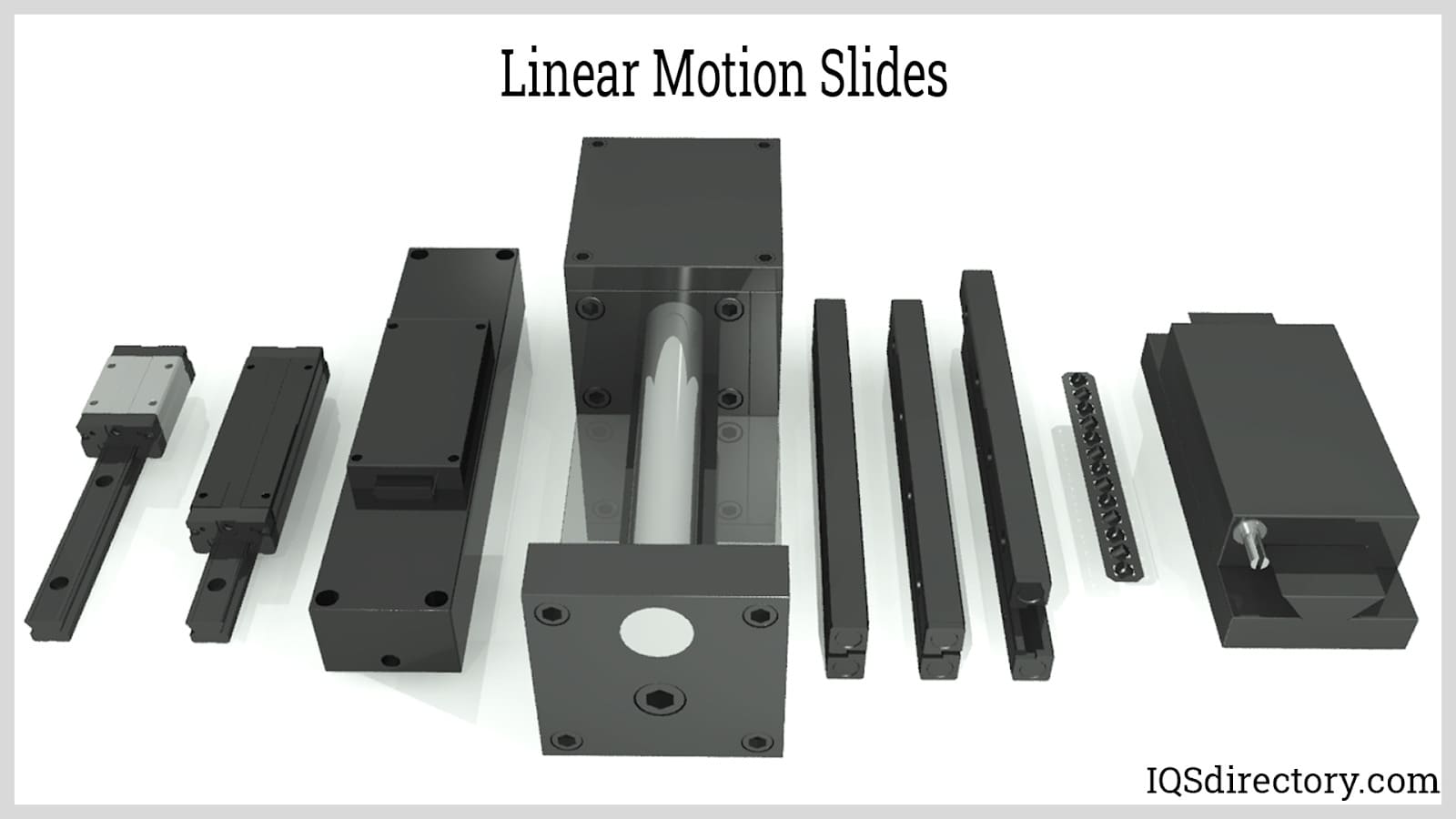

Linear Bearings Linear Slides

Linear Slides Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services